Efficient Production: How to Make Limestone Pellet Using Advanced Extruder Machines

Updated: 21 Oct 2025

22

Limestone is one of the most abundant and versatile natural resources used in construction, agriculture, and industry. From neutralizing acidic soil to serving as a filler in various products, its benefits are vast. However, in its powdered form, limestone can be difficult to handle, store, and apply efficiently. That’s why pelletizing limestone has become an increasingly popular solution across industries.

If you’re wondering how to make limestone pellet, this guide explains the step-by-step process, key equipment involved, and how an extruder machine for sale in Pakistan can help local manufacturers and agricultural businesses produce high-quality limestone pellets efficiently.

Understanding Limestone Pelletizing

Pelletizing transforms powdered limestone into small, uniform pellets that are easier to transport, spread, and store. These pellets are durable, dust-free, and dissolve slowly, making them ideal for agricultural use where gradual soil enrichment is preferred. The process can be achieved through either wet granulation or dry extrusion granulation, depending on available technology and desired pellet properties.

Among these methods, dry extrusion granulation is gaining popularity because it eliminates the need for drying and reduces operational costs — perfect for businesses in developing regions like Pakistan where energy costs are a concern.

Step-by-Step: How to Make Limestone Pellet

Here’s a detailed look at how to make limestone pellet efficiently using modern granulation technology:

1. Limestone Preparation

The process begins with selecting high-purity limestone rocks and crushing them into fine powder. A consistent particle size (typically below 75 microns) ensures proper binding during pelletization. If moisture is present, the material should be dried before further processing.

Crushed limestone powder is stored in silos or hoppers before being mixed with binders (if necessary) to enhance pellet strength. While some methods use water and organic binders, the dry extrusion process can often form pellets without any additional liquids.

2. Mixing and Conditioning

In this stage, the powdered limestone is mixed evenly in a blending unit to achieve uniform consistency. Optional additives like bentonite or lignosulfonate can improve pellet durability and control release rates when used in agriculture. The goal is to create a homogenous mixture that can be compacted easily in the granulator.

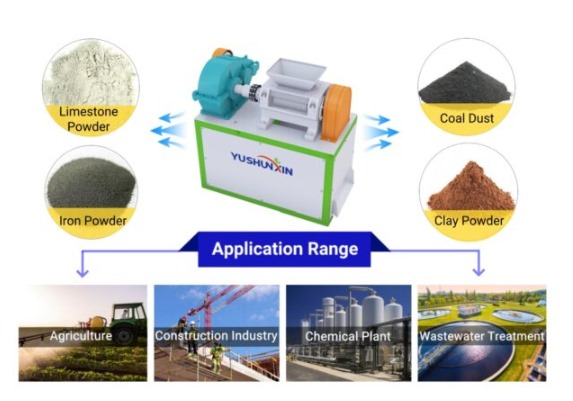

3. Granulation with an Extruder Machine

The granulation process is the heart of limestone pellet production. This is where the extruder machine plays a vital role. The powdered limestone mixture is fed into a double roller extrusion granulator, where it is compressed between two counter-rotating rollers under high pressure.

This compaction process forms dense sheets or strips of limestone material, which are then broken and cut into uniform granules — typically ranging from 3 mm to 10 mm in diameter. The pellets formed by this dry granulation method are solid, smooth, and ready for use without requiring further drying.

4. Screening and Classification

After granulation, the pellets pass through a vibrating screening machine. Oversized pellets are crushed and recycled back into the granulator, while undersized powder is returned to the mixer. This ensures a consistent pellet size and minimizes waste.

5. Cooling and Packaging

Since the dry extrusion process generates little to no moisture, the pellets typically require minimal cooling. Once cooled, they can be bagged using automatic weighing and packaging systems. The result is a uniform, dust-free product suitable for industrial or agricultural markets.

Advantages of Using an Extruder Machine

Using an extruder-type granulator for limestone pelletizing offers several operational and economic benefits:

- Energy Efficiency:

The dry process eliminates the need for a dryer or cooler, saving significant energy and lowering production costs. - Compact Design:

The machine has a small footprint, making it suitable for small to medium-scale operations or for integration into existing fertilizer or mineral processing plants. - Low Maintenance:

Extruder granulators are designed with durable rollers and minimal moving parts, which reduces wear and maintenance requirements. - Customizable Pellet Size:

The roller molds can be customized to produce pellets of various sizes depending on application needs (agriculture, chemical, or industrial use). - Environmentally Friendly:

The process produces minimal dust and waste, helping maintain cleaner and safer work environments.

Extruder Machine for Sale in Pakistan

With growing demand for agricultural efficiency and industrial raw materials, many local businesses are looking for an extruder machine for sale in Pakistan to start limestone pellet production. Modern manufacturers now offer complete dry granulation lines capable of producing 1–3 tons of pellets per hour — ideal for medium-scale operations.

One reliable option is the Limestone Powder Granulation Machine available from extruder-granulator.com. This machine is designed for dry granulation without the need for heating or drying, saving up to 30% in operational costs. It can process limestone, dolomite, and other mineral powders into high-density pellets.

For businesses in Pakistan, this same supplier also lists an extruder machine for sale in Pakistan through its NPK fertilizer manufacturing page. These machines are versatile and can be used not only for fertilizer production but also for limestone and mineral pelletizing — making them a smart investment for multiple industries.

Economic and Environmental Benefits

Producing pelletized limestone locally can offer major advantages for Pakistan’s agriculture and construction sectors:

- Reduced Import Dependence: By manufacturing pellets domestically, local industries can cut transportation and import costs.

- Improved Soil Health: Farmers gain access to high-quality lime pellets that are easy to apply and enhance soil productivity.

- Job Creation: Setting up pelletizing plants creates employment opportunities in equipment operation, maintenance, and distribution.

- Cleaner Production: The dry granulation process minimizes waste, dust, and emissions, aligning with eco-friendly production goals.

Conclusion

Learning how to make limestone pellet is a valuable step toward improving both industrial efficiency and agricultural productivity. The process — from crushing and mixing to granulating and packaging — can be efficiently handled with a dry extrusion granulator.

For those seeking to start production locally, investing in an extruder machine for sale in Pakistan offers a cost-effective, energy-saving solution that can deliver high-quality pellets with minimal environmental impact. With the right equipment and proper process management, businesses can transform ordinary limestone powder into profitable, sustainable products for the growing market.

Please Write Your Comments